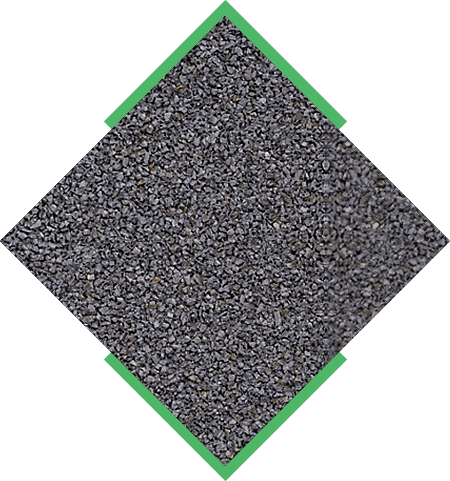

Crumb rubber is made by reducing scrap tires into small, uniform granules. Inherent reinforcing materials, such as steel and fiber, are removed, along with other types of inert contaminants, such as dust, glass or rock.

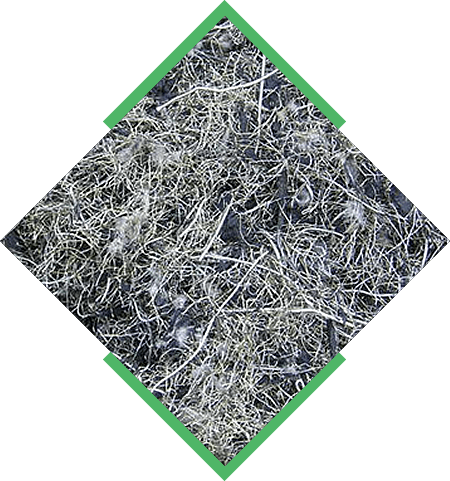

With the expansion of economies worldwide, the demand for steel is burgeoning. While steel manufacturing goes from strength to strength there is a solid case for using recycled steel to augment supply through recycling. Steel wire is an important by product of rubber tyre recycling. Tyres are shredded and the high quality steel wire that is used in the making of radial tyres is extracted to enable steel manufacturers to recycle it. Klement’s steel is processed under strict quality control.

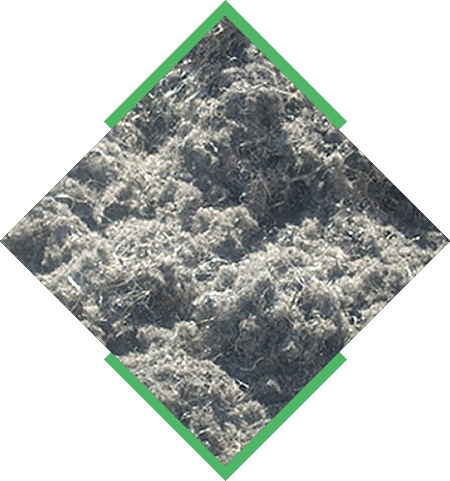

Nearly 10% of the recycled tyre is composed of textile fibre that is often called fibrous "fluff". In modern tyres, this fibre is mainly composed of Polyester that is used to enhance the tyre performance and quality. Fibre from recycled tyres find many applications such as construction mixes like concrete and stucco. It is also used as a clean up material as the fibre is highly absorbent and it is often used in carpets as an underlay. Fibre is also used as a filling for sound dampening, as well as a reinforcing additive for rubber, plastic and composite materials. Recycled fibres from Klement are of the highest quality.

Tire-derived aggregate is made by reducing scrap tires into shreds as a sustainable and cheaper alternative to conventional fill in civil engineering applications. Shreds three inches or smaller are used as drainage material, and shreds of six inches and more are used as permeable fill for infrastructure. Tire-derived aggregate has 1/3 the weight of soil, drains 10 times better than soil, insulates 8 times better than stone and costs less than sand and gravel.